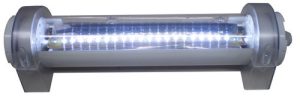

Stationary hot air generator HTV-N

Characteristics

- Type

- stationary

- Power source

- gas

- Power

-

Max.: 7,000,000 W

Min.: 90,000 W

Description

Constructed from carbon or stainless steel to the highest specification, HTV-N Indirect Process Air Heaters provide clean hot air at up to 350°C. The heaters can be fitted with inspection and cleaning doors, condensate drains and water-resistant gaskets where the process demands and utilise specialist welding procedures to reduce the risk of particulate deposits on the heating surface.

HTV-N is supplied complete with a fully matched burner for gas or oil firing and an optional economiser for very high efficiency operation. The modulating burner provides exact control of the process air discharge temperature.

All HTV-N Indirect Process Air Heaters are custom designed to suit the specific demands of each installation. Process air flow ranges between 1,000 to 100,000 kg/h with air discharge temperature up to 350°C.

HTV-N heaters simplify and reduce the total cost of installation and operation when compared to traditional indirect heating methods. Particularly when planning new installations, the reduced space demand and ease of operation greatly reduce overall costs and normal operating maintenance demand.

Typical Process Duties

Tobacco Drying

Milk Drying

Salt Drying

Chemical Process

Food Process

Fertilizer Manufacturing

Paper Manufacture

Starch Production

Gum Arabic Production